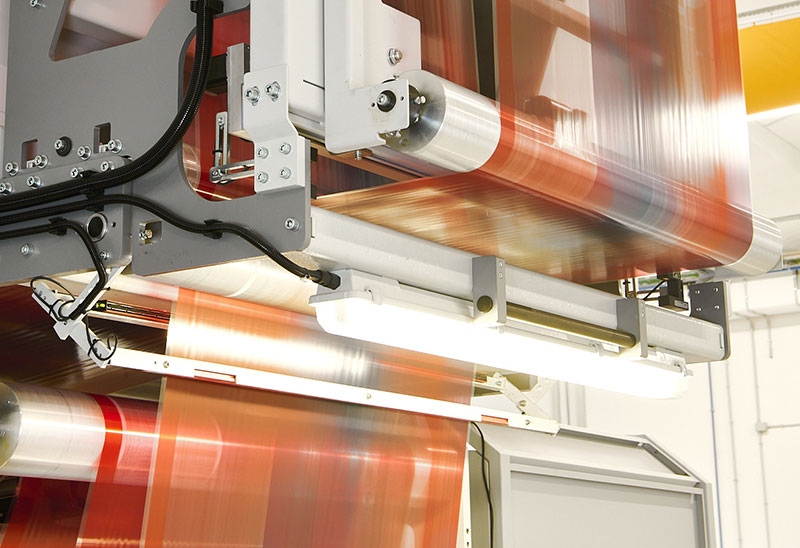

At G.M. Grafica, we operate a fully integrated and constantly evolving machinery fleet. Our production is driven by advanced technologies, including water-based flexographic printing, solvent-less lamination, high-precision slitting machines, and preforming lines for bags and stand-up pouches.

Innovation in our processes goes hand in hand with the design and development of eco-sustainable packaging, such as paper-based laminates and mono-material structures (e.g., PE+PE, PP+PP) that support circular economy goals.

Up to 10 colors.

Up to 10 colors each.

1 dedicated to triplex structures

1 dedicated to duplex structures.

Automated vertical warehouses with capacity for 4,000 pallet spaces, handling raw materials, semi-finished, and finished goods.

2 Automated vertical storage systems for up to 15,000 printing cliches.

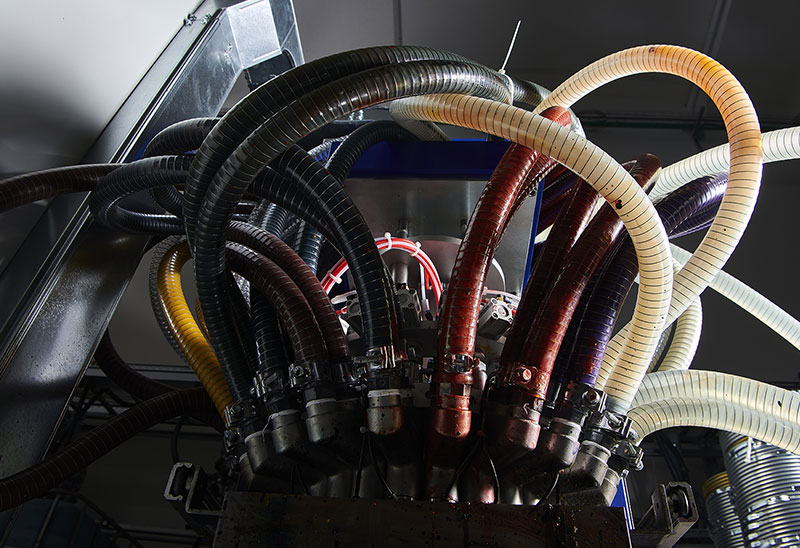

1 for water-based inks

1 for solvent-based inks.

We ensure the highest product standards through rigorous in-house testing and R&D:

- Coefficient of Friction (C.O.F.) analysis

- Thickness measurements

- Tensile strength tests

- Hot Tack seal testing

- Bond tests

- Color measurement & control

- Product design, researxh & development.